RTC Furnace Upgrades

RTC IR FURNACE RETROFIT - Add 15 Years to your Furnace. We retrofit RTC IR furnaces and extend RTC IR furnace useful life another 15 years with low cost retrofits and upgrades. Replace or fix chamber, cooling sysem or belt stutter. Or simply update with a networked computer, controls & electricals. Often we can improve the performance of your industrial furnace, or in any event bring your production furnace or laboratory oven back into compliance with original factory specifications. Call us with the model and serial number of your IR furnace and we can work with you to determine cost effective options for your furnace application.

FIX CHAMBER or COOLING SYSTEM to renew furnace performance. Ship your RTC furnace chamber to us, or to cut downtime, just order a replacement chamber or cooling section. We manufacture replacement modules that install so easily that often they can be reinstalled by your own staff using our detailed step-by-step instructions. Or we can do it for you. Our replacement cooling sections are built out of high strength aluminum and are stronger and more efficient than the original RTC modules.

PROCESS CHANGES? Often we can change the belt speed range or correct low speed problems with the belt on an RTC IR furnace to accommodate your process changes. An oxygen or moisture analyzer can be added if sampling systems ports are present.

UPGRADE FURNACE COMPUTER? The computer on RTC IR furnaces can be replaced with a new RAID1 managed platform computer system and power supply to increase system reliability and uptime.

BUY A USED FURNACE & UPDATE? If you are looking for a new furnace, you may be interested in a popular cost-saving solution: Purchase one of the used RTC IR furnaces, ovens or dryers and have it shipped to our factory where we can inspect and install new controls computer, wiring, motor and/or accessories as necessary to bring the furnace back to original factory specifications, customize it for your application and assure a minimum of 15 year life in most cases. Contact us for good sources for a used furnace.

Below are descriptions of some of choices commonly selected to change processes, expand production or just keep the production-line on track.

Common IR Furnace Upgrades

| SERIES | DESCRIPTION | APPLICATION |

|---|---|---|

| Computer RAID1 System  |

Replace existing RTC furnace computer with a new Dell Optiplex managed computer with Windows 7 operating system and latest furnace software. Includes Ethernet TCP/IP and wireless-N network interfaces for remote monitoring and diagnostics. | Upgrade failed or obsolete computer and older furnace software. Applies to all RTC furnaces with Opto22 control system using LCM4 controller with either B3000/B3000-B SNAP racks and/or 4D16R, G4A8R and G4D32RS bricks. |

| Computer/Controller New Computer & LCM4 replace RTC Classic G4 controller  |

Replace obsolete Win95/98 computer and Opto22 Mistic Classic ARCnet controller with new RAID1 Dell Optiplex Computer and LCM4 Ethernet controller. New Computer/LCM4 can interface with existing B3000 I/O racks and/or Mistic G4 I/O bricks. Replace all I/O with new B300-B SNAP racks with all new I/O if required. |

Upgrade to update obsolete equipment with latest computer OS and LCM4 Ethernet controller. Applies to all Radiant Technlology furnaces with Computer interface and G4 control systems including Opto22 Mistic G4LC32 Classic and Classic G4LC32SX controller systems with G4D16R, G4A8R AND G4D32RS bricks. |

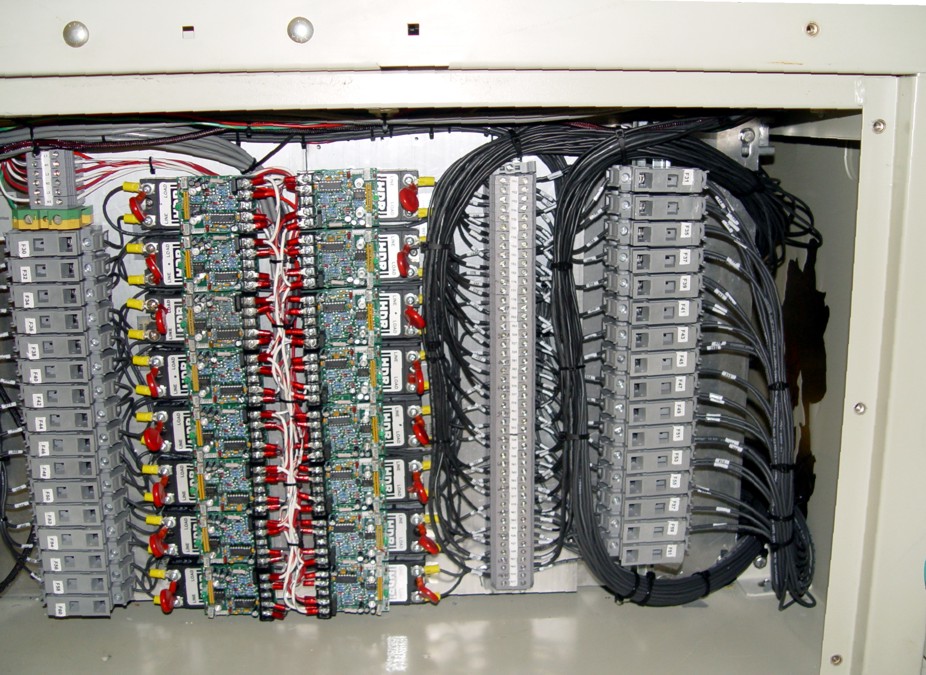

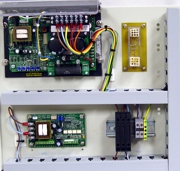

| Controls/Electricals Replace RTC computer, control system and electricals  |

New RAID1 Computer, PLC controller and I/O racks, lower electricals, transport drive motor and motor controller.

A new sampling system can be added or if existing , new oxygen and/or moisture analyzers can be installed. Upgrades typically include:

|

A complete system overhaul can add 15 to 20 years life to an outdated production furnace. Applies to most RTC furnaces including those with early RTC dedicated controllers and/or old DOS-based computer controlled systems. Models:

|

CAWC Cooling System |

New Design plug an' play replacement for RTC CAWC Cooling systems. An update to the original design, this replacement cooling system is stiffened to add strength and additional cooling capacity. Manufactured of high strength 6061-T6 aluminum. | Direct replacement for most CAWC closed atmosphere water cooling systems in RTC

infrared furnaces. Specify number of cooling modules and furnace belt width. |

| Chamber Replacement Baffle & Chamber Assemblies  |

In our factory we can rebuild your existing RTC IR furnace heating chambers to original specifications. Or order new replacement IR furnace heating chambers complete with insulation and quartz belt guides factory installed to reduce downtime. Also new chambers can be designed to PH4 to accommodate greater product height or PH1 to accommodate tighter production control requirements. |

A replacement IR furnace chamber can be a cost effective alternative to purchasing a new furnace due to damage to existing chambers or new product

requirements. Applies to most RTC IR furnaces:

|

| OA & MA with OSS Oxygen & Moisture Sampling  |

Sample system includes three port sampling plus source sampling, sample pumps and switching manifold. Add or replace oxygen analyzer and/or moisture analyzer. On newer RTC or FurnacePros IR furnaces the OSS can be integrated with the furnace control software | Applies to most Radiant Technology, GreenBridge Technology or FurnacePros IR furnaces. |

| Motor Controller Improved Motor control  |

New motor controller provides advanced signal loop isolation and permits smooth operation at lower speeds. Eliminates rough starts and inconsistent

belt speed performance, especially at belt speeds under 130 mm/min (5 ipm). - MCCI Isolation kit. - MCC Motor Control (incl MCCI). - Transport Motor kit (includes all above). This transport drive is built into all new IR furnaces. |

The inexpensive MCCI kit can usually be installed by owner's maintenance techs in less than 1 hour and integrates well with standard RTC furnace

transport motor controllers. These kits apply to most Radiant Technology furnaces, Radiant Tehhnology ovens, Radiant Technology dryers, GreenBridge Technology or FurnacePros Infrared furnaces with 1/5 hp or 1/4 hp dc drive motor and control system. |

Selected Models

Applicable RTC Radiant Technology Corp furnace model retrofit and upgrades for:

RTC AG-series AG-1215,

AG-1224, AG-1515, AG-1524

RTC C-series C-915, C-924, PV-309

RTC D-Series D-615, D-624, D-915, D-924D-924, D-936, D-948, D-956

RTC LA-series LA-304, LA-306, LA-309, LA-310 (also LF-304, RA-306, RF-306, RA-316, RF-316)

RTC

PV-series PV-314, PV-614, PV-624, PVD-309, PVD-609, PVD-614, PVD-615 PVD-624

RTC S-Series S-910, S-910X, S-914, S-914X, S-915, S-915X, S-1215, S-1215X,

S-1224, S-1224X, S-1515

S-1524

RTC S-Series Hydrogen S-910H, S-910XH, S-914H, S-914XH, S-915H,

S-915XH, S-1215H, S-1215XH,

S-1224H, S-1224XH, S-1515H, S-1524H

RTC TF-series TF-909, TF-915,

TF-924

... and many others.

Retrofit to extend RTC IR Furnace useful life

Add 15 years to your furnace with new Computer, Controls & Electricals, belt control.

Fix chamber, cooling system, belt stutter

Upgrade chamber, controls & cooling

Low Prices on OEM Parts & IR Lamps

| Used Equipment |

|---|

| Used Equipment |

| eMail for Quote |

Corporate Offices:

30025 Alicia Pkwy #417

Laguna Niguel, CA 92677 US

P: 1.949.218.4996

Office Hours:

Monday - Friday

8:00 AM - 4 PM PST